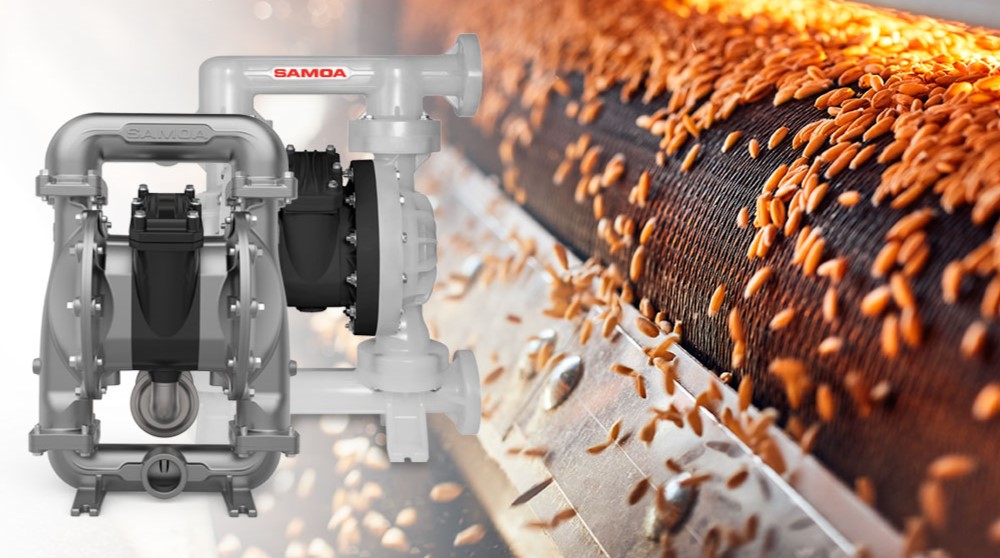

A leading European open corrugated cardboard manufacturer relied on SAMOA diaphragm pumps for glue transfer applications during its manufacturing process. This renowned, boasting over 30 plants and 4000 employees, produces all kind of open corrugated cardboards including grease-resistant, waterproof, or self-adhesive.

After testing pumps from two competing brands for pumping glue known as corrugating adhesive with low viscosity, they were not satisfied. They experienced serious issues with ice formation and pulsations, which could imply slow air motor operation, preassure loss, and therefore costly inefficiencies for the company. Additionally, the problem of pulsations increases vibrations in the system’s pipes and could even damage the pumped fluid. Moreover, the competition did not provide readily available spare parts.

UP20 pumping glue in a cardboard factory

SUCCESS STORY

UP20 pumping glue in a cardboard factory

Challenges to solve

Pumping high-viscosity fluids.

Ensuring reliability and durability of equipment.

Availability of spare parts.

Resolving ice formation issues.

This is how we face the project

To address the challenges of pumping glue, a 2" pneumatic double diaphragm pump from the SAMOA PIVOT series with part number UP20A-BFC-NNN has been installed. The central body and air chambers are constructed from aluminum, while the fluid chambers and manifolds are made of ductile iron. All wetted parts are composed of Nitrile (Buna-N) offering excellent resistance to oils and greases. Additionally, the pump's materials resistance can be configured to suit specific application requirements. With a flow rate of 650 l/min, the pump's bolted construction ensures optimum sealing to prevent leakage.

The PIVOT Series Air Distribution System has shorter and oversized evacuation air passages that effectively evacuate air from the chambers to the atmosphere, preventing freezing. Its operation is reliable and prevents pump from stalling. Maintenance is straightforward due to the low number of parts, and the cartridge design of the air valve simplifies installation.

The solution

After two months of continuous operation without incidents, it can be assured that the switch from the competition to our pump has been a success, as the customer is highly satisfied for the following reasons:

- SAMOA´s UP20 requires less air supply and consumes less air than the competitor´s pump they had before to provide the same flow rate. This results in less wear, increased service life of pump’s moving parts and less energy consumption for SAMOA’s pumps in comparison with the competitor´s model.

SAMOA UP20 |

COMPETITOR’S MODEL |

|

Air supply pressure |

4,8 bar – 69, 6 psi |

6,2 bar – 90 psi |

Air consumption |

1810,2 l/min – 63,9 scfm |

2007,1 l/min – 70,2 scfm |

- The disappearance of ice formation significantly increases reliability and improves performance.

- Minimizes maintenance costs. The Air Valve Cartridge is a key component to ensure quick and easy maintenance thanks to its intelligent design.

Pneumatic Piston Pumps Accessories

This is an example of quick text to fill the body of the card with some content in order to present it properly in page. We hope you like it.

Image gallery

Real success stories about our products

Check out our best application stories.