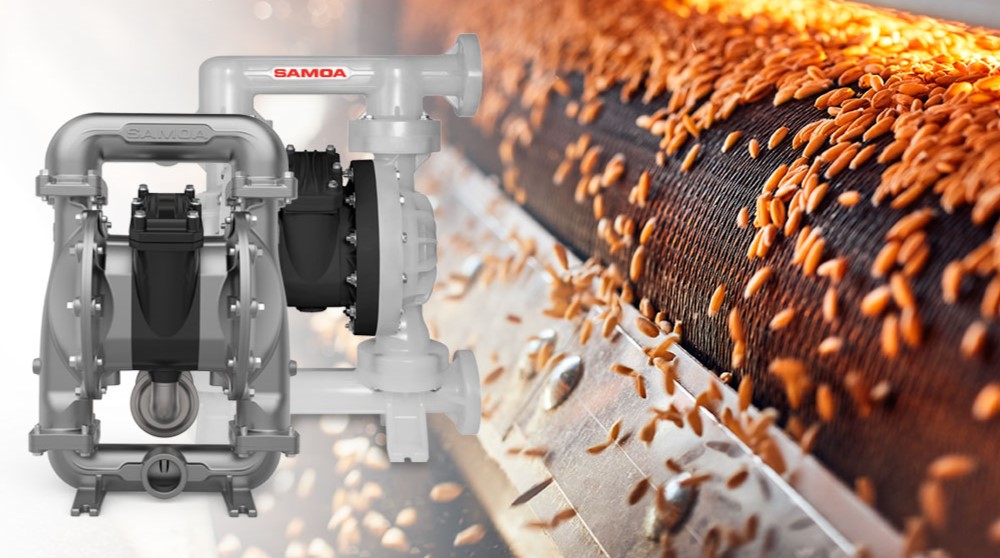

Kapachim is a leading company in the chemical industry, specializing in manufacturing primary surfactants, specifically Betaine, for a wide range of industrial, personal care, and household products. Betaine is highly abrasive, and its use in competitors' pumps has caused considerable damage to the wetted components. This damage, resulting in downtime for pump maintenance, has led to significant losses in both time and resources. The customer urgently needed a high-quality pump capable of withstanding abrasion during long periods of intense pumping.

UP05 pumping betaine in a chemical industry

SUCCESS STORY

UP05 pumping betaine in a chemical industry

Challenges to solve

Resistance to corrosion and abrasion

Increased performance

This is how we face the project

The main constraint in this case is the pumped fluid. Betaine, one of the primary surfactants used in detergents and other formulations for personal and household care, is corrosive and could deteriorate pump materials over the medium to long term. Therefore, a 1/2" (13 mm) UP05 pump from the PIVOT series was chosen. This pump can reach a flow rate of up to 51 l/min (13.5 gal/min). Its fluid chambers and manifolds are made of PVDF. The valve seats and valve balls are made of Teflon, and the diaphragms are made of PTFE (Teflon with Santoprene). Other key aspects that led the customer to choose our pump include:

- Proven air motor: The patented "Smooth Start Shifter" (3S) actuator ensures a reliable start system, preventing the pivot from stalling. Furthermore, the air is discharged directly into the atmosphere through two large evacuation ports, preventing freezing and pump slowdown.

- Easy maintenance: The pneumatic motor of the PIVOT series pumps has the fewest moving parts in the market, and its assembly is effortless due to the cartridge design. The air valve module can be replaced in a few minutes without removing the pump from service.

- Reduced air consumption: Thanks to the rapid movement of the pivot, air consumption is reduced and the output flow is optimized compared to the competition.

- Universal pump standards: Matches the relative dimensions of main competitive brands, allowing for an easy swap-over.

The solution

Our goal has been to demonstrate the superior quality of SAMOA pumps compared to others. To achieve this, the UP05 pump underwent inspection after three months of continuous operation pumping betaine. The conclusions drawn from this inspection by the customer were:

- Superior performance of the pump compared to its competitors' equivalents.

- Significantly lower noise level.

- Great reduction in vibrations.

- After four months of continuous operation, the pump is working perfectly and has not required any maintenance operations.

Pneumatic Piston Pumps Accessories

This is an example of quick text to fill the body of the card with some content in order to present it properly in page. We hope you like it.

Real success stories about our products

Check out our best application stories.