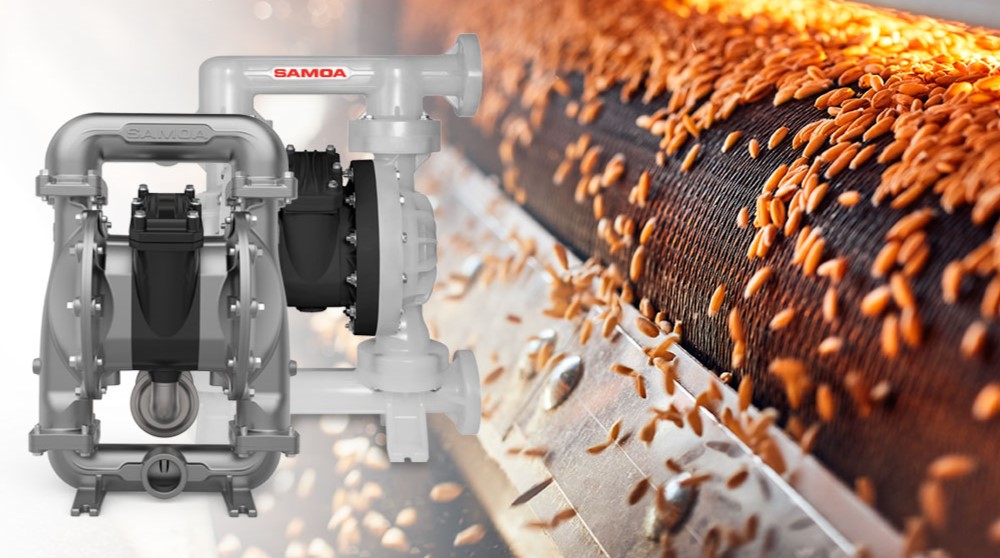

To address these challenges, we implemented our Nex·U fluid management system in the lubretruck. During the project design phase, the distributor travelled to our factory up to three times to seek an optimal solution, receiving training on the selection and installation of the equipment to ensure an effective installation.

The installation includes equipment such as U·Net, U·Powers, U·Counts, solenoid valves, high-flow meters, and an integration platform with the client’s management system. All of this is accessible through a wireless network and virtual keypads.

Key features for the success of our system:

- Detailed operation records: Precise information about the type and amount of lubricant supplied, the operator responsible, and the tasks performed.

- Real-time transaction export: Automatic stock updates and transaction logging with ERP integration capability via 4G connection.

- Remote data access: Reports accessible from any authorized device, enabling easier control and analysis.