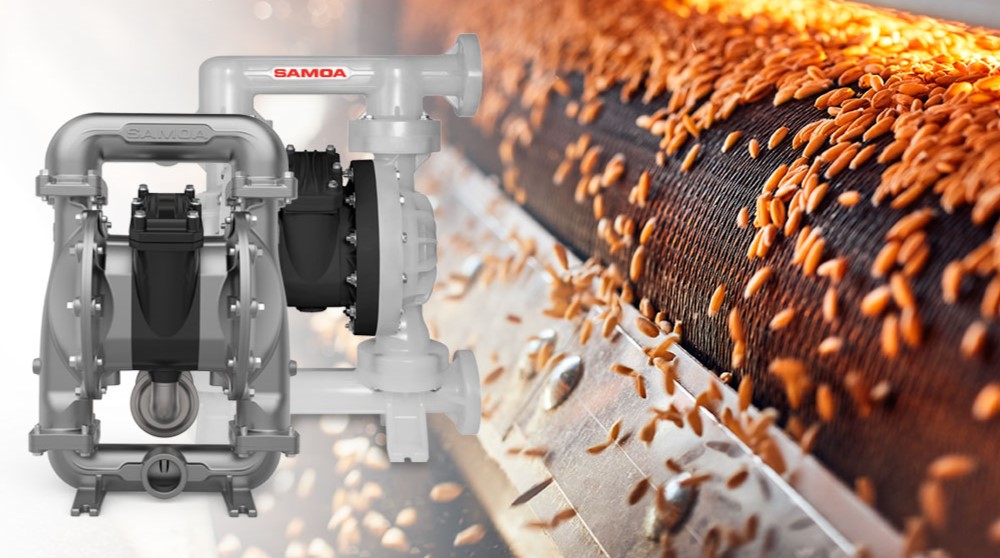

Mining vehicle maintenance requires special equipment built with high-quality materials to ensure optimum performance in extreme working conditions and temperatures. In addition, such equipment needs highly reliable technology to achieve the required lubrication demands. Hence, the equipment for this installation was selected, considering both the transferred fluid characteristics and the pumping location. SAMOA offers high-capacity pumps for this application, with high-capacity reels and high-flow control valves.

Two grease piston pump models were installed. First, the high-performance pump PM60 12:1 (532130), suitable for transferring large grease volumes (greases up to NLGI-2). Manufactured with high-quality materials allowing optimum performance in extreme working and temperature conditions, such as outdoor applications. This pump is used for tank refilling, even when using long pipes or hoses. Second, the pump PM35 60:1 (530610), is used in forced lubrication with high delivery rates (greases up to NLGI-2).

Two piston pumps designed for transferring and supplying oil were also incorporated into the installation. One of them is a piston pump PM2 3:1 (354120) for applications where medium flow rates is needed. For situations requiring long distance oil supply with high flow rates, we included a piston pump PM4 5:1 (347120).

SAMOA installed three different open type hose reels, manufactured in steel, for regular use and abuse in Intensive Duty applications. The RM100 (508225) model is suitable for high flow rates at medium and low pressure, while the RM150 and RM34 models (508810, 505224) are only for low pressure. To dispense the fluid at each delivery point, we chose two types of electronic metered control valves, EC30 model (365535) and EC70 (365655) model for high flow. Both products are suitable for oil and other fluids and manufactured in aluminum.