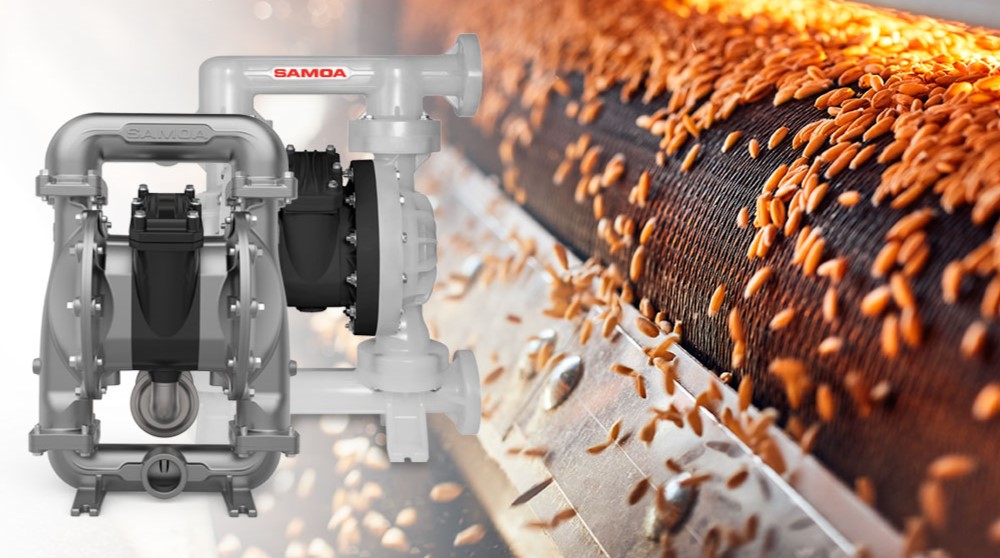

An international company, located in Latvia, that supplies equipment and materials for digital printing and packaging needed an economical solution to transfer offset ink to its final location in the offset printing machine. Until now, they had been using equipment that pumped the ink from small 2kg (4.4 lb) cans. By doing this they incurred high operating costs mainly resulting from the excessive number of wasted containers and the associated residual ink.

SUCCESS STORY

SAMOA PM45 11:1 installed in the Latvian printing industry reduces waste and operating costs.

Challenges to solve

Reduce operating costs associated.

Reduce waste and residual ink.

Enhance productivity.

This is how we face the project

To solve these challenges, we installed a SAMOA PM45 pump with single post hoist, operated by compressed air, to transfer ink. These pumps are light enough to be used with a single post lift but heavy enough to handle day-in and day-out pumping demands.

The pump selected can transfer high viscosity ink from 200 kg (441 lb) drums, so the end user can avoid obtaining ink from 2 kg (4.4 lb) cans. This pump meets the requirements for continuous ink supply in centralised installations, allowing ink to be consistently transferred from this large drum to the final location on offset printing machines. The pump is fixed to a single lip follower plate and the weight of the air motor, pump, and mounting bracket makes priming the pump easier.

The PM45 pump installed allowed the customer to effectively reduce operating costs by reducing the number of drum replacements required, and therefore ink purchase and workforce costs. The customer now uses larger ink containers thanks to our pump, allowing them to improve productivity and minimize both waste and the cost associated with its disposal.

The solution

PUMPMASTER 45 - 11:1 ratio ink pneumatic pump, 200 kg drum with pneumatic pump hoist and gravity inductor package improved the installation by:

-

Saving costs as the price of buying in bulk 200 kg drums is lower in cost than buying many smaller 2 kg cans.

-

Waste reduction since switching from 2 kg drums to 200 kg drums can result in a reduction of up to 3%, which also has an impact on the costs associated with waste disposal.

-

Ease of storage because the customer does not have to buy a hundred 2 kg cans of ink and store them at the plant, instead a single 200 kg drum is sufficient.

Pneumatic Piston Pumps Accessories

This is an example of quick text to fill the body of the card with some content in order to present it properly in page. We hope you like it.

Real success stories about our products

Check out our best application stories.