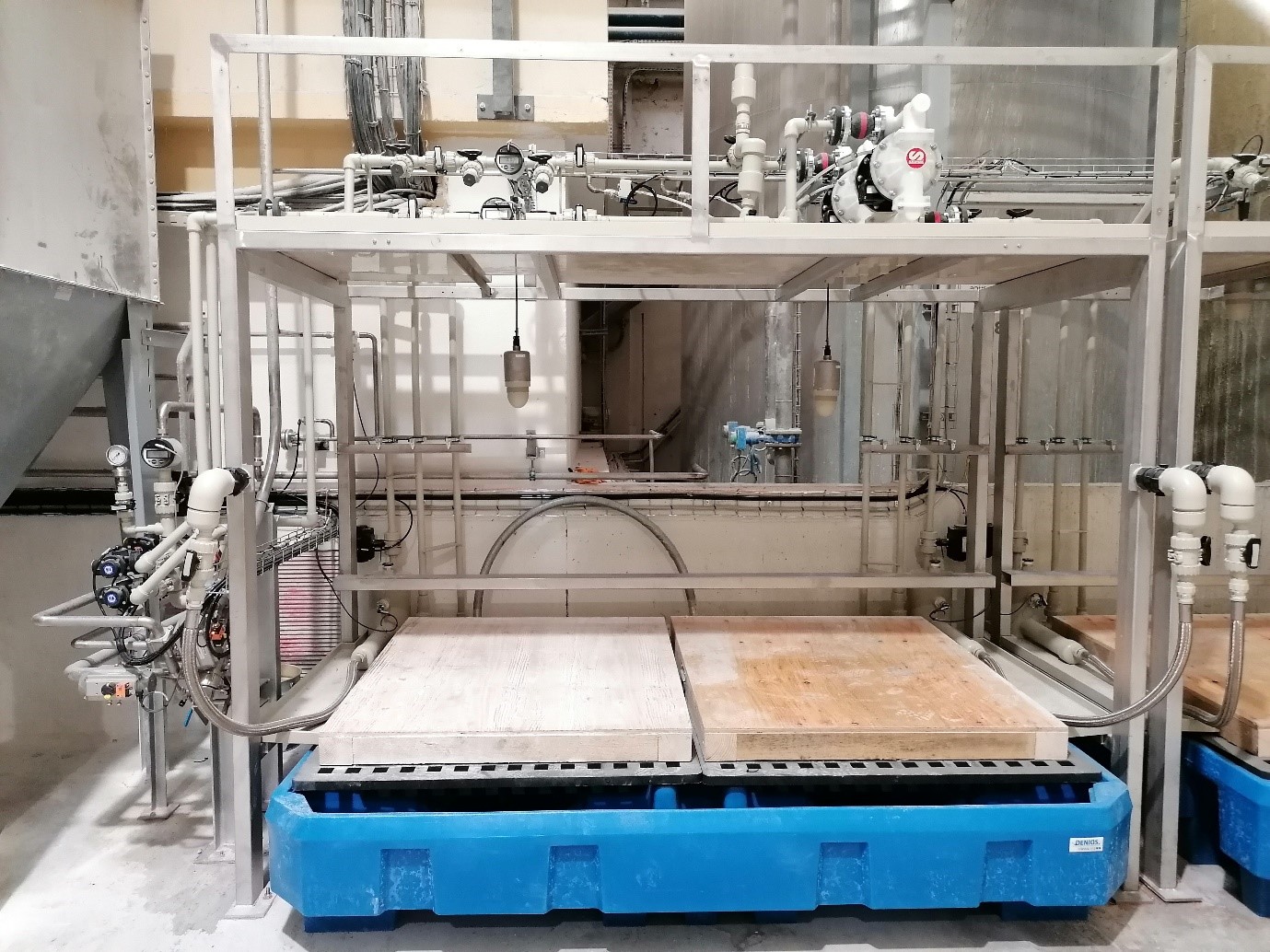

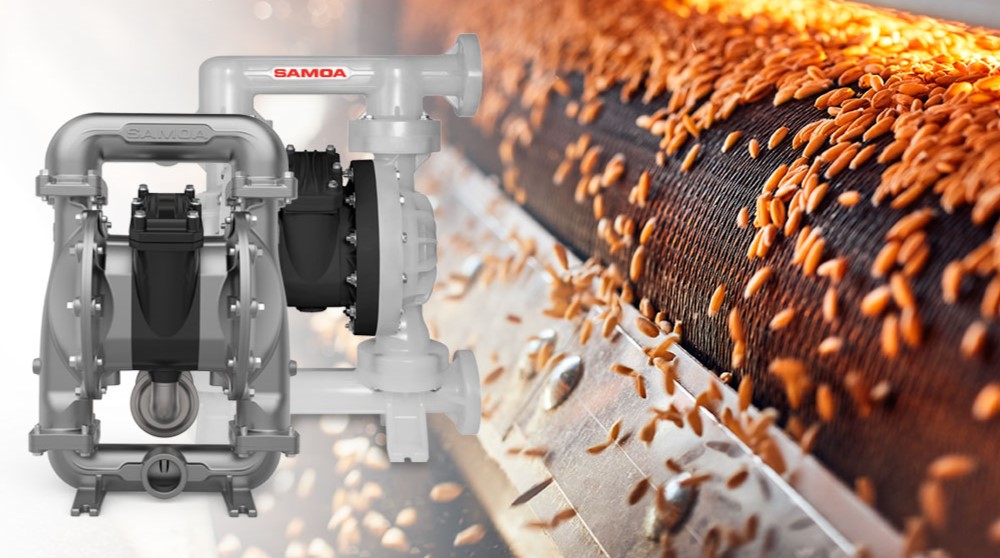

A major paint manufacturing group based in France, known for its expertise in the development and production of decorative paints, required pumps with low pulsations to ensure precise biocide dosing in their production process, maintaining high standards of quality and efficiency. The group operates across several countries, with highly advanced production facilities that emphasize eco-friendly solutions and product excellence. SCOREL, a trusted distributor, was instrumental in providing SAMOA products for this installation.