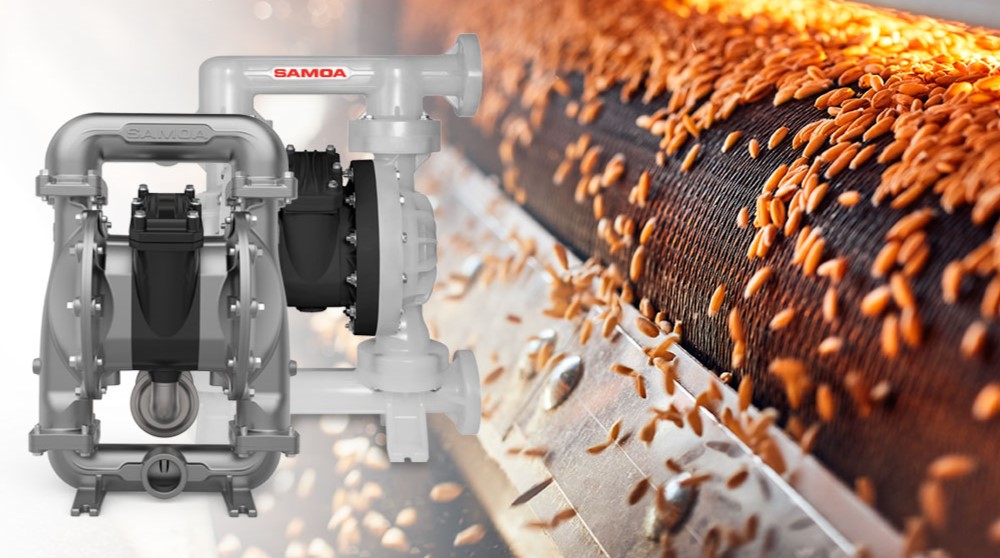

The SAMOA PM80 50:1 pumps are known for their durability and reliability, thanks to top-quality materials and their innovative technology. With their high pumping capacity and pressure ratio, they can easily meet the dispensing needs required for this application.

SAMOA’s piston pump reliability, due to its fast-reciprocating movement to avoid stalling during operation, is crucial in any manufacturing industry like this one. These industries cannot afford downtime, caused by pumping equipment, in their production lines. For this reason, SAMOA’s PM80 air motors, designed for an efficient heat transfer and without energy-consuming springs to avoid icing or motor failures, are key for this installation.

The user was highly satisfied with the result of the first two pumping systems installed. They were able to pump the whole 185 kg drum in less than eight hours, and the flow delivery met the requirements on each application point. Furthermore, given the high drum replacement at these stations, we included in the kit the inductor plate bleed rod for priming aid, which was very valuable for the user.

After the pumping systems installation, there was a noticeable reduction in grease waste thanks to the double post inductor used to aid grease priming. The inductor, along with the follower plate, helps make the most out of the grease drum content in comparison to other brands, eliminating air pockets and removing the grease from the drum walls.

The user, who has been highly satisfied with the performance, efficiency and level of finish of the SAMOA pumps, has requested more units in this plant.