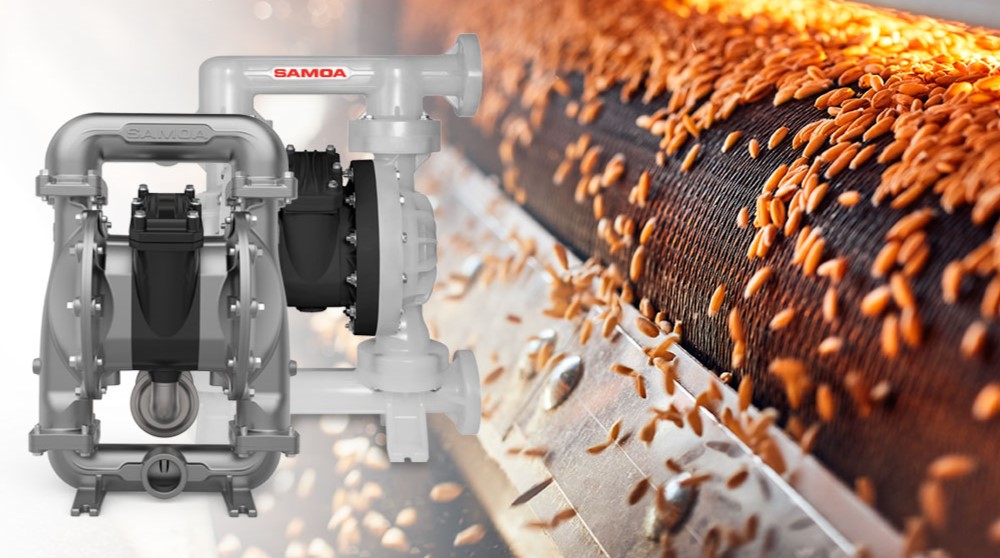

A food processing company located in Hungary, was experiencing poor operation performance caused by an old diaphragm pump. This pump transferred wastewater from the wheat starch production, and specifically struggled with fluids containing elevated sugar levels and increased viscosity. This led to multiple issues. such as priming and cavitation challenges, flow rate inconsistencies, vibrations, excessive air consumption, and stoppages caused by frequent breakdowns.

SUCCESS STORY

UP20 at wheat starch production plant

Challenges to solve

Solve pump priming issues and cavitation

Improve performance issues

Reduce air consumption

This is how we face the project

Installing SAMOA's diaphragm pump has proven to be a success for various reasons. First, these pumps are engineered with a robust construction that enables them to excel in handling abrasive fluids. This is an important feature since, in this specific application, the wastewater may contain up to 65% of solid particles

Another key factor contributing to SAMOA's diaphragm pumps success is their simple design, for a reduced number of pump parts. This simplicity facilitates maintenance procedures, making them easier and faster to service. The shorter maintenance and less effort translate into reduced costs and minimized downtime. Moreover, the SAMOA PIVOT Series has effectively addressed a range of issues, including unwanted vibrations, noise or pulsations, through their innovative Frictionless Pivot Shaft Air Valve design and its incredibly fast changeover shift. Additionally, a reduction in the air consumption has environmental and cost-saving benefits for the end user.

The solution

The SAMOA PIVOT Series diaphragm pumps, offer a comprehensive solution for optimizing this industrial process. These pumps provide a range of benefits that enhance operational efficiency, with their low pulsations and vibrations.

One of the standout advantages of these SAMOA pumps is their ability to significantly reduce air consumption, while ensuring a smoother, more even flow. Their self-priming capability eliminates the inconveniences associated with priming issues, simplifying startup procedures.

Considering that wastewater can contain sodium hydroxide or hydrochloric acid, which are corrosive substances, we recommended two different pump models: UP20B-FPS-PMA and UP20A-BSS-STZ-A. The first one is manufactured in polypropylene, and the second one has an aluminum air motor with stainless steel housings.

Pneumatic Piston Pumps Accessories

This is an example of quick text to fill the body of the card with some content in order to present it properly in page. We hope you like it.

Real success stories about our products

Check out our best application stories.