The end user is the largest aluminium manufacturer in the Czech Republic, and one of the biggest in Europe. They manufacture top-quality aluminium packaging, foil, sheets and strips. The company had previously installed diaphragm pumps to transfer various solvent-based paints used in the aluminium packaging printing process. However, these pumps caused several issues in their production, including leakages, loud noise, high pulsations, and vibrations. In addition, these pumps had a high air consumption. By using these pumps, the company suffered from frequently, expensive and difficult servicing, that led to continuous downtime on production processes.

SUCCESS STORY

1" Diaphragm pumps in aluminium industry.

Challenges to solve

Reduce maintenance costs

Reduce air consumption

Ensure reliable operation

Reduce pulsations and vibrations

This is how we face the project

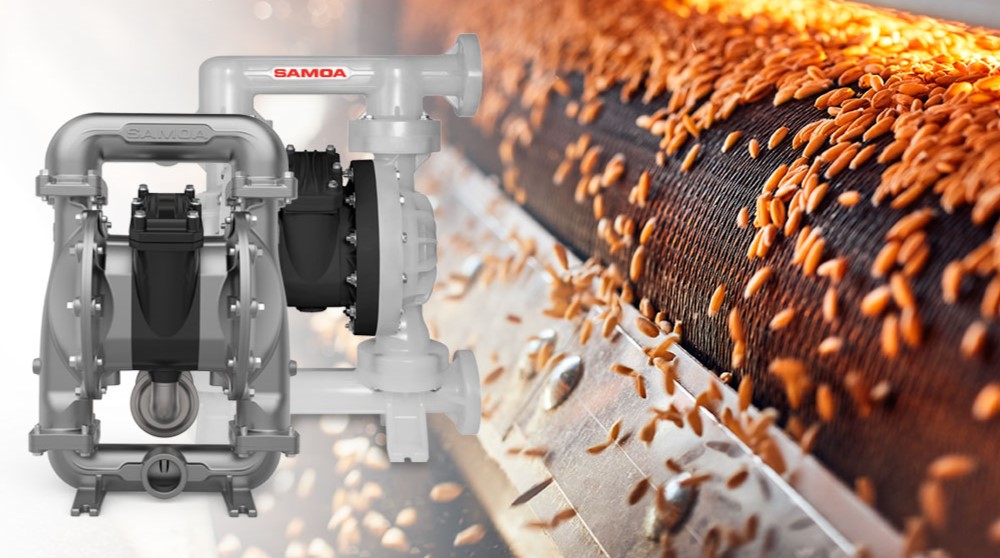

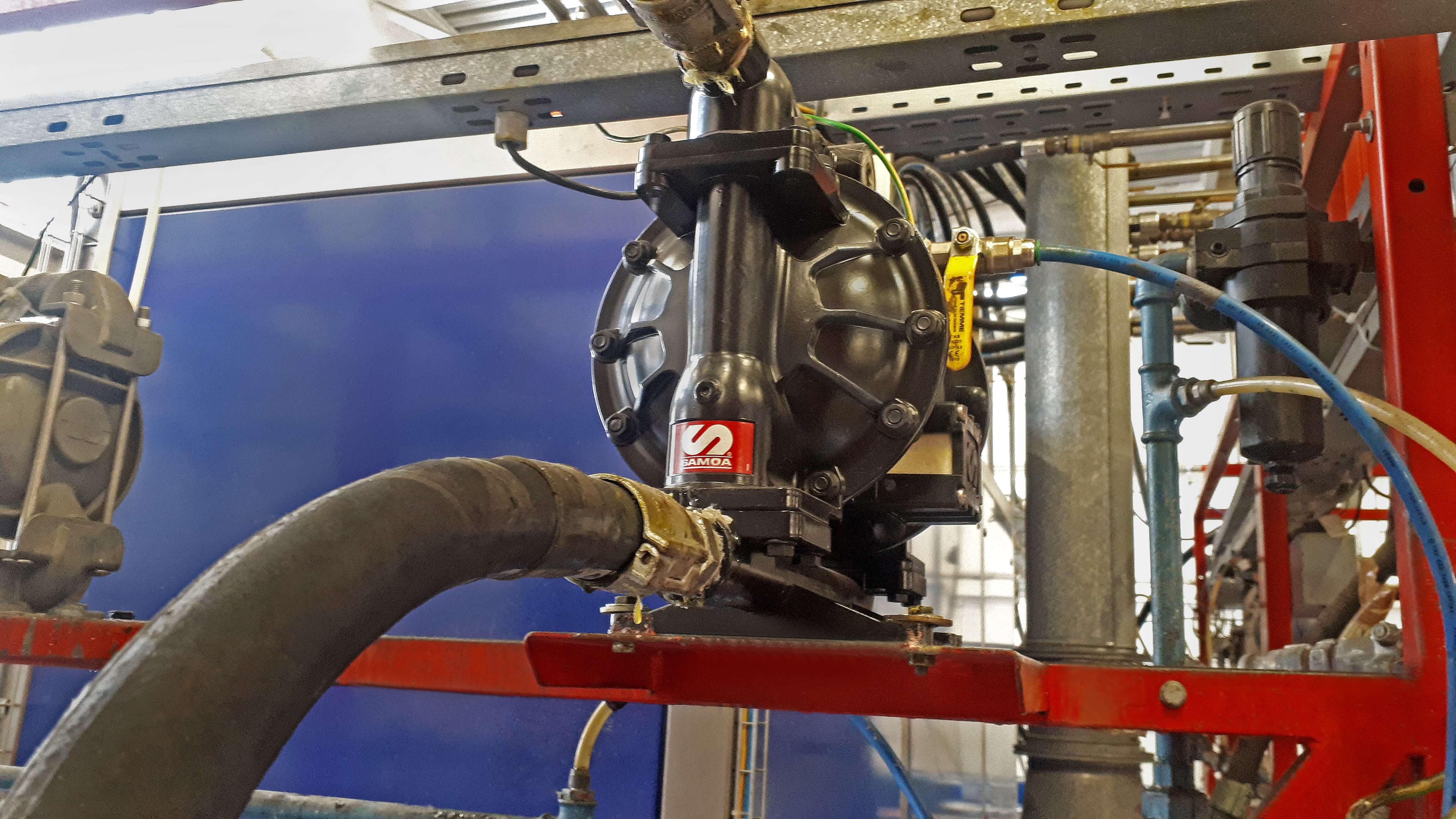

Considering the end user’s requirements and the problems needed to be solved, three aluminium SAMOA 1” Pivot Series diaphragm pumps were offered. These pumps have the diaphragms and balls made of PTFE (Teflon) to ensure the right chemical compatibility between the pump and the solvent-based ink to be pumped.

As the ink mixing process involves volatile solvent-based inks, the area is considered an explosive atmosphere, making it necessary for the offered pump model to be ATEX certified. Therefore, air operated diaphragm pumps were the best choice.

The solution

The end user experienced notable improvements due to the innovative Frictionless Pivot Shaft Air Valve design featured in the SAMOA PIVOT Series diaphragm pumps. These pumps enhance flow performance, ensuring smoother and more consistent operation while reducing pulsation and vibrations. The air valve's rapid changeover minimizes air consumption, enhancing energy efficiency. Moreover, the design guarantees a no-stall, no-icing operation, resulting in a reliable performance. The pump's universal design facilitates easy installation, and its reduced number of parts streamlines maintenance, effectively minimizing downtime. As a result of implementing SAMOA PIVOT Series diaphragm pumps, the end user observed a reduction in air consumption, leading to lower energy consumption compared to their previous pumps. Additionally, the innovative air valve design contributed to decreasing pulsation and vibration, which was particularly beneficial for ink transferring process.

The user highly appreciated the enhanced ease of maintenance, thanks to the air valve cartridge design and the simplified pump structure with fewer components. This not only reduced downtime but also lowered maintenance costs, ensuring a more efficient and uninterrupted production process.

Pneumatic Piston Pumps Accessories

This is an example of quick text to fill the body of the card with some content in order to present it properly in page. We hope you like it.

Image gallery

Real success stories about our products

Check out our best application stories.